Gigaphoton: Fabscape Machine Learning Data Platform for Predictive Maintenance

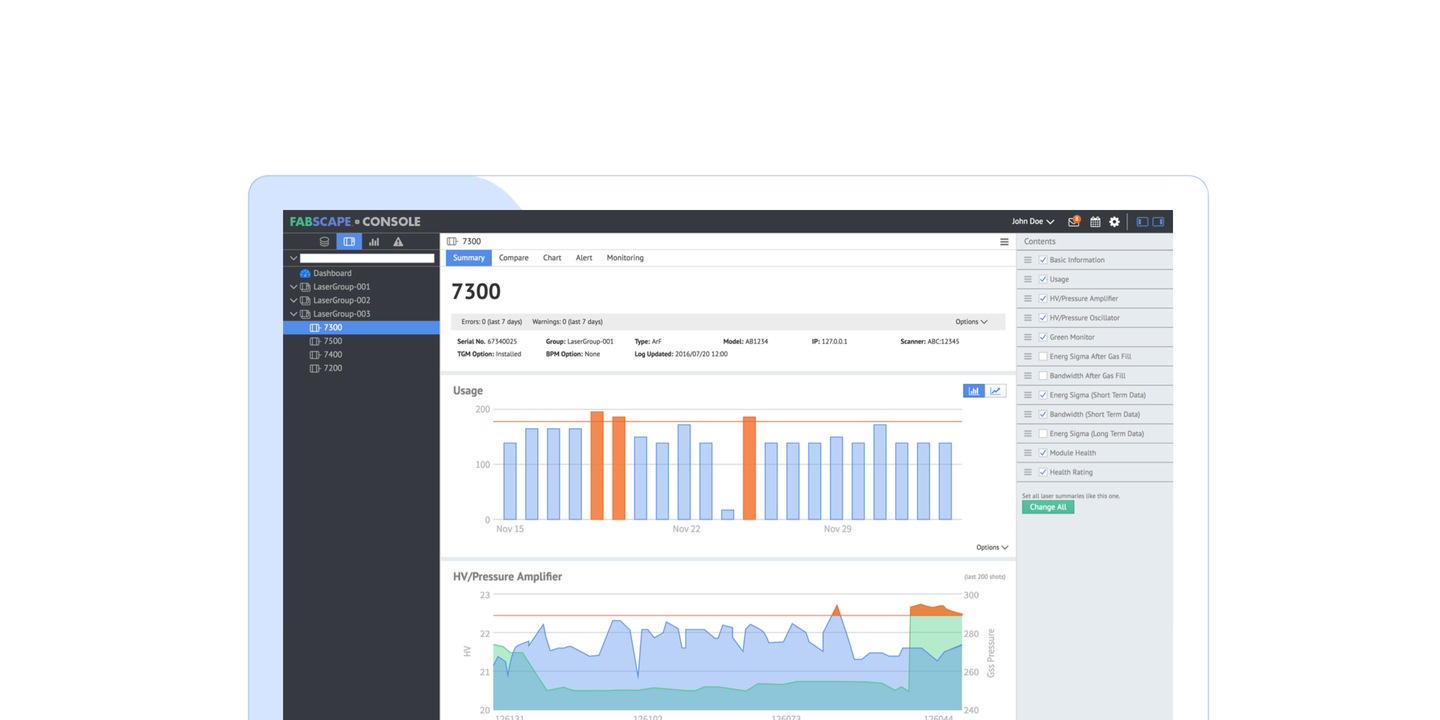

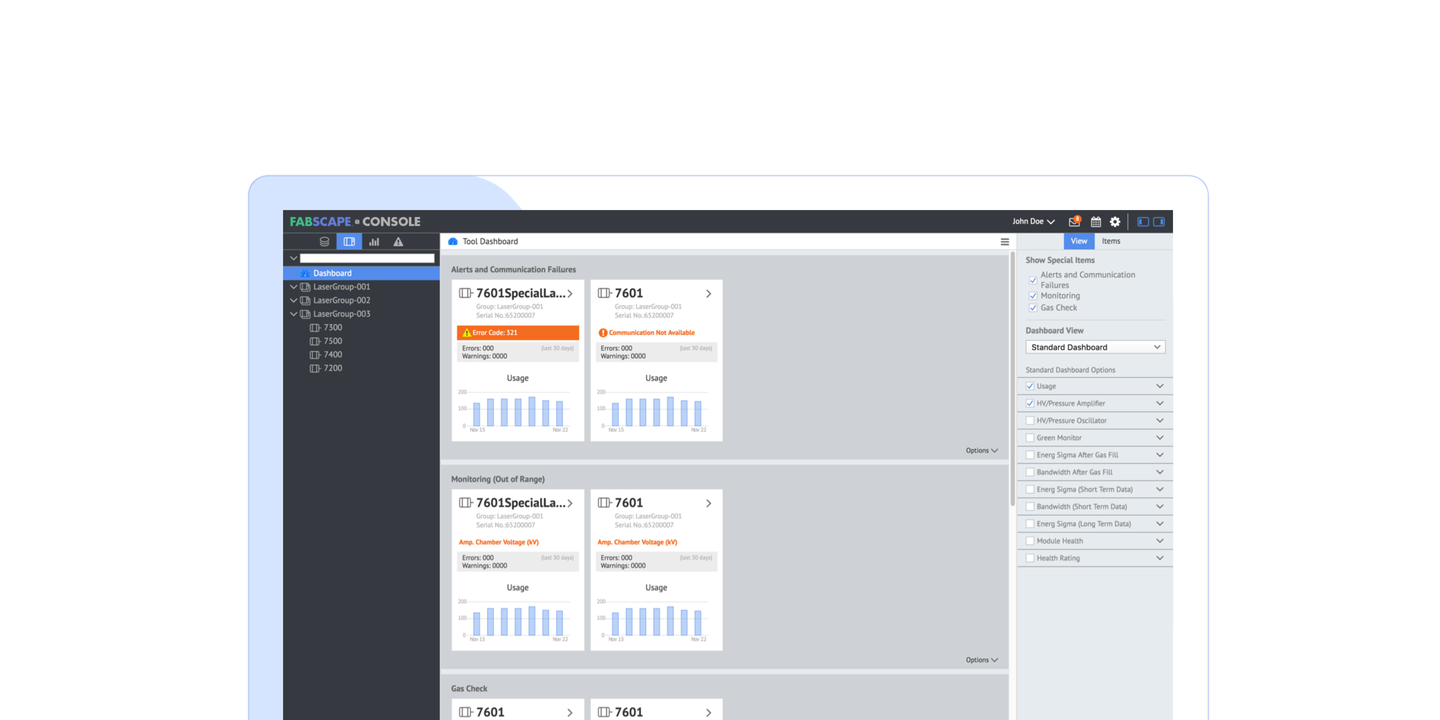

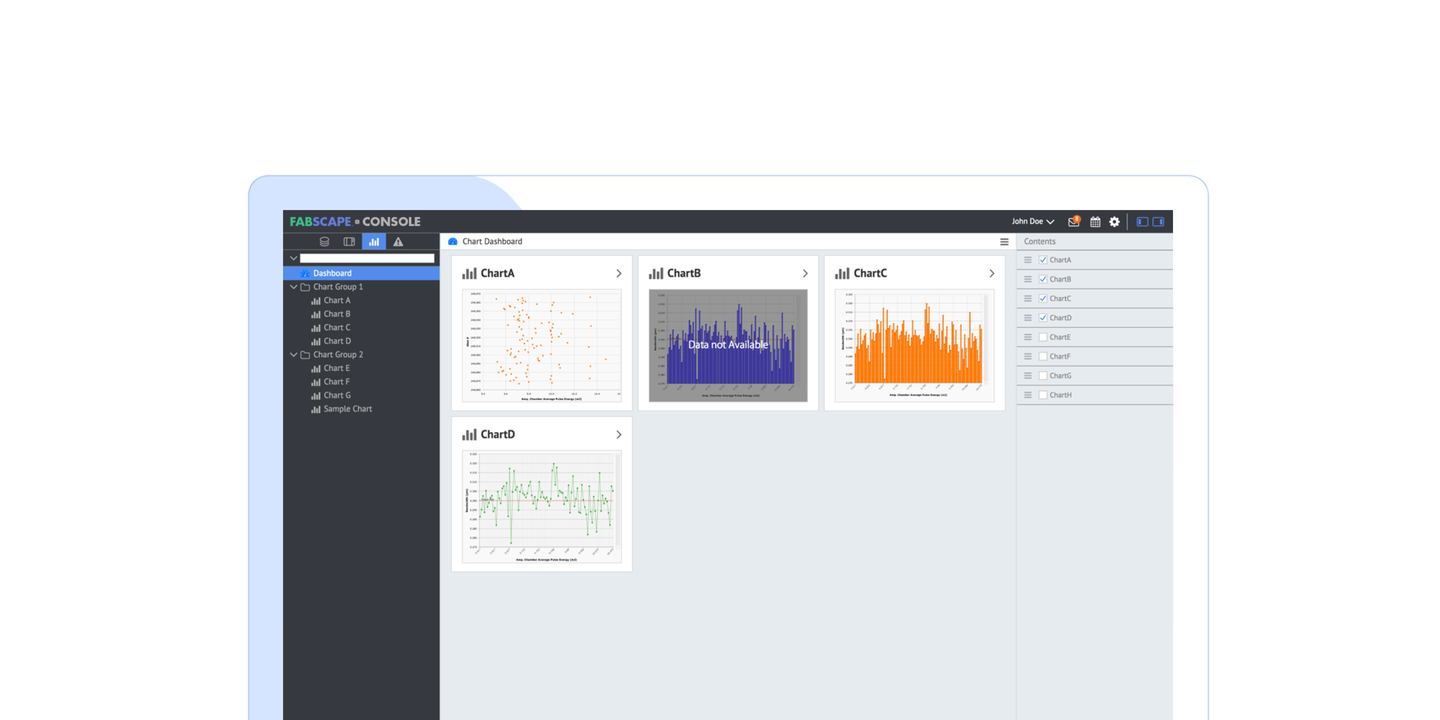

Over the last 3 years, GRAYBOX has closely partnered with Gigaphoton to design and develop an extensible platform for monitoring and analyzing equipment performance within semiconductor manufacturing facilities. GRAYBOX designed a microservice based architecture with a service mesh, allowing for performance monitoring, data aggregation, reporting, analysis and maintenance scheduling.

Overall Outcome

Gigaphoton released, “FABSCAPE™” an extensible platform to allow integration with any vendor’s tools and data, while allowing the operators to maintain control of their sensitive data.

The Results

GRAYBOX architected and developed the core plugin set required for the system’s basic functionality, as well as several additional modules to continue expanding the capabilities.

-

7Major chipmakers adopted within 9 months

-

12Core plugins available out of the box

-

∞Custom Plugins possible by using SDK

The Overall Problem

Gigaphoton sought out to design and develop a platform that would resolve the issues around data ambiguity between multiple vendors in the semiconductor industry. Collecting, monitoring and surveying critical performance data across lithography equipment in a consistent way was just not possible. Our goal was to conceive an application that would allow customers to collect and analyze data in a unified format, allowing for a more meaningful and accurate comparison.

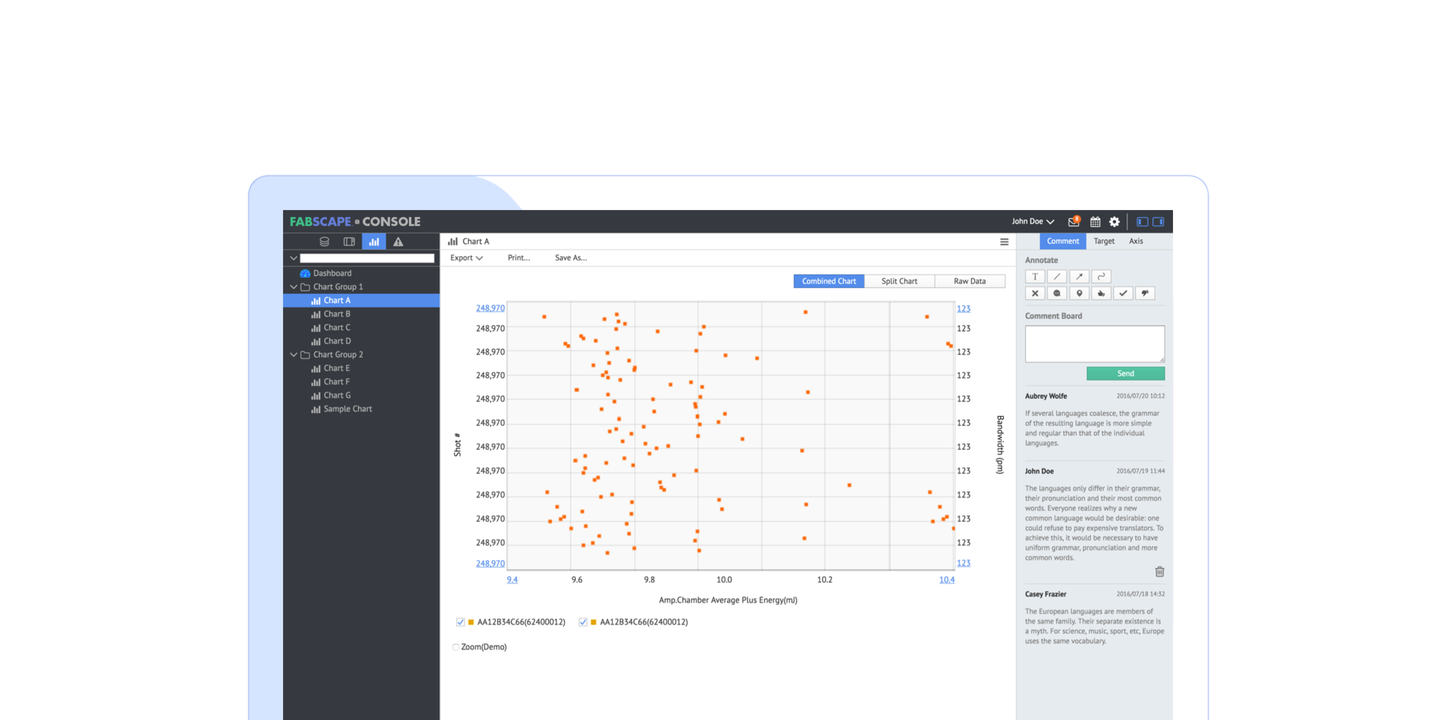

The platform needed to be flexible and modular, allowing customers to modify the application in a way that met their unique needs. An open architecture would also allow customers and 3rd party developers to design their own custom plugins or drivers that further extend the platform beyond the core, making it more adaptable for manufacturers.

We also needed to ensure that data collection, aggregation and reporting could be accurate, fast and reliable. This would be paramount to the success of the Gigaphoton's platform. Research and due diligence needed to go into understanding semi-standards, proper time series data consumption, storing, monitoring and visualization to guarantee that the correct information was available for customers to make meaningful decisions.

Finally, security is always of critical concern, so the platform also needed to be deployed behind firewalls and offline in an air-gap system. This made the challenge of installing and upgrading the platform even more complex. Maintaining a consistent, controllable environment would be another consideration to account for during planning and platform architecture.

I am confident that FABSCAPE’s™ bold new open software approach can allow device manufacturers to gain a deeper and more uniform understanding of equipment data and help spark new innovations through collaboration, and partnerships both inside and outside of our traditional industry players, contributing to the further growth of our industry.

Our Solution

1. A modular system, built with plugins.

We decided on a micro service based system where all plugins and drivers would run in their own individual Docker containers, allowing the system to be modular. With a core set of plugins that would ideally cover the majority of customer requirements, a full development kit would be available for 3rd party developers and customers to modify their set of plugins to fit their business needs. This would also make installing and upgrading more efficient by allowing components to be updated and versioned independently.

Finally, leveraging Docker would mean that all development environments could be maintained consistently. GRPC and Rest API's would be used to communicate between plugins and drivers, allowing plugin developers to develop in their preferred languages, further enhancing platform fluidity. Building the platform in a modular way would make it dynamic, powerful and extensible.

2. So. Much. Data.

"Making sense of the enormous volumes of data generated by varying semiconductor manufacturing tools continues to be a challenge for our customers..."

– Katsumi Uranaka, president and CEO of Gigaphoton.

In order to ensure we could accurately and reliable capture vast amounts of data, in real time, we relied on Postgres. We're constantly evaluating new opportunities to explore and expand on the platform capabilities, so we actually utilize a few different types of databases depending on the plugin, but for data collection and distribution, it's been stable and snappy. We also utilize amCharts for additional data visualization and reporting. It provides multiple features and extensibility that we're able to implement within the Fabscape platform.

3. It only helps, if it's secure.

Another benefit of building the system with containers would be that we could install packages locally, on-premises for customers and control the actual environments. Data security is critical in the industry, and ensuring that this system would be installable locally, offline for manufacturing facilities was a rigid requirement. Not providing this security would be a non-starter. Plugins also maintain a deep permission structure, making communication across plugins more secure.

Working with Gigaphoton has been a true partnership, allowing us to set new standards in the semiconductor industry. We’re proud to be at the center of Fabscape’s design, from early whiteboard diagrams, to technical architecture, to the open platform available today.

Our Services

Utilizing resources such as Golang, React, GRPC, Docker, Openshift and Kubernetes, GRAYBOX designed a microservice based architecture with a service mesh, allowing the system to be completely based around modular plugins, while maintaining adherence to a system wide permissions system.

Our Results

Our Results

Following the initial announcement of, “FABSCAPE™” for the monitoring and analysis of semiconductor manufacturing equipment, at least seven major semiconductor chipmakers began implementing it into their operations within 9 months of launch.

GRAYBOX continues technical architecture and senior development leadership for multiple development teams contributing to the project. This has led to a true partnership as GRAYBOX leads the conceptual platform design strategy and forward-thinking necessary to push the limits of the industry.

-

7Major chipmakers adopted within 9 months

-

12Core plugins available out of the box

-

∞Custom Plugins possible by using SDK